The AIR 1 System

See more details

AIR 1

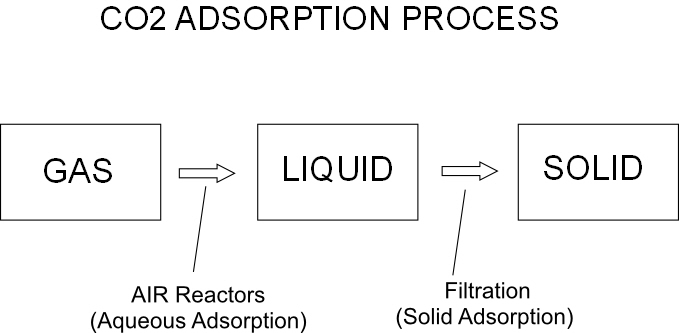

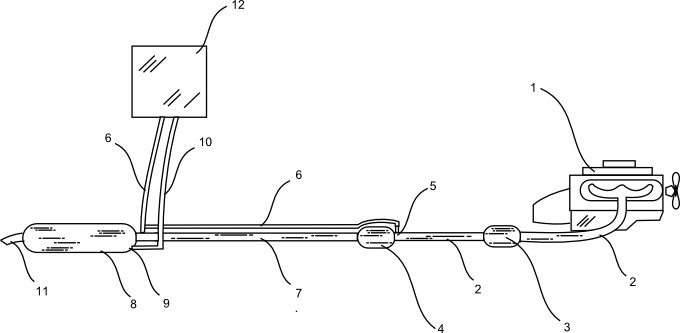

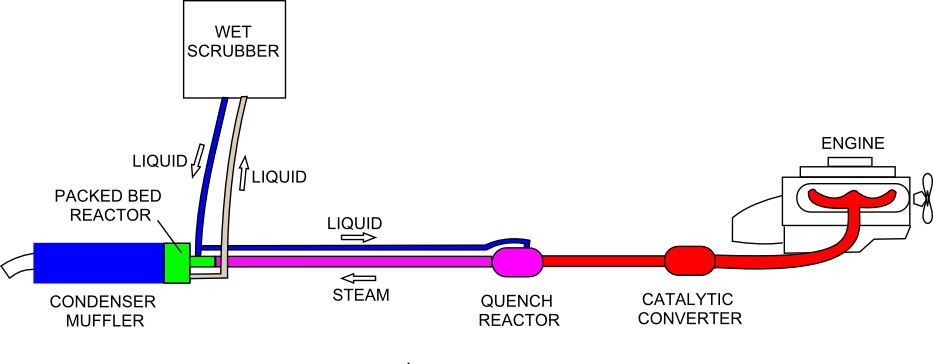

A Patent Pending Wet Scrubber System for internal combustion engines is designed to remove CO2, CO, as well as numerous particulates and VOC’s in the exhaust gases. The system utilizes well known principles used for scrubbing pollutants from coal fired plants and also for extraction of contaminants from soils. The novel application of this invention is the adaptation and utilization of these technologies in the exhaust systems of trucks and automobiles.This invention works in automobiles and trucks with or without a catalytic converter and all types of vehicles with internal combustion engines regardless of fuel, including diesel, gasoline, syngas, CNG, etc.

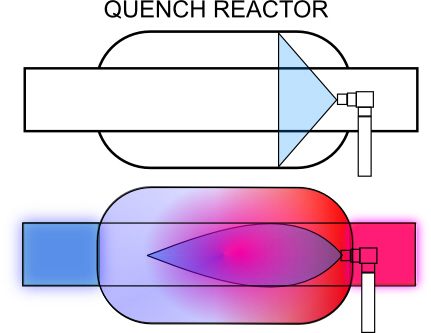

The system is made up of a scrubber solution which is a mixture of propylene glycol and water. This liquid is safe for the environment, biodegradable and is even used in foods. The fluid has specific qualities to make it ideal as a working fluid for this system. The fluid has a freezing point of -60f and a boiling point of 360f. The fluid condenses from steam to liquid at a nominal temperature of 266f (dependent on barometric pressure) The fluid is injected into a Quench Reactor which sprays cold fluid into the hot exhaust gas stream coming out of the catalytic converter. This instantly produces steam comprised of extremely small atomized droplets.

The steam interacts with the exhaust gas to cool the gas and to scrub the exhaust of pollutants and particulates within the Impingement Tube. This interaction continues as the steam condenses throughout the system, removing more contaminants.

The steam then enters another chamber called the “Wet Bed Reactor” which is a perforated tube located directly before the muffler. The WBR is packed with a stainless-steel wool material which is sprayed by nozzle with the same working fluid as used in the Quench Reactor. The steam and exhaust gas pass through the liquid cooled and wetted steel wool which forces the gas to come into close contact with the working fluid. This causes a phase reaction, causing the steam to rapidly cool and condense into liquid. The remaining steam continues to condense and be collected by a modified muffler designed to collect the liquid.

The liquid is then picked up by an electric pump and run through a radiator to further cool the working fluid. The fluid exits the radiator and enters a filtration system which removes particulates as small as .2 microns. The filtration system can remove much smaller particulates by adsorption as well as absorption where ionic bonds remove VOC’s such as benzine and formaldehyde. The scrubbed fluid then returns to a storage tank, where a second electric pump delivers the recycled fluid back through the system to the Quench and PB reactors.